- Info@chandanprocess.com

- +91 89800 82792

Chandan Process is one of the main Manufacturers and Distributors of Polished LAB GROWN DIAMOND and

Supplies loose Polished LAB GROWN DIAMOND to the Jewellery Trade Globally. The Manufacturing Facilities

in Surat.

The Success of Chandan Process is Attributed to our customer-centric Philosophy, the

standard

Standards We Maintain, The Meticulous Manufacturing Skills of our Employees, and Fair trading Practices

Which We actualize throughout the globe. This together with our core Family values ensures a loyal

Customer base everywhere in the world.

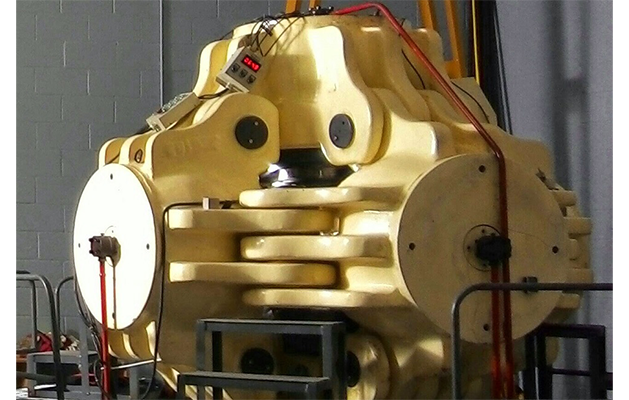

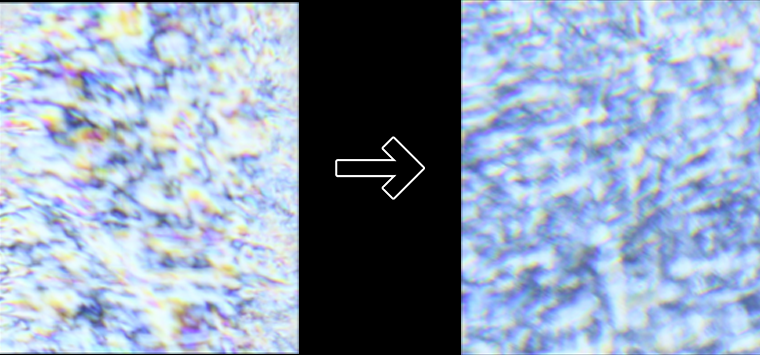

Diamonds with a slight colouring go through the HPHT process to make them appear whiter. Slightly tinted diamonds may also be colour-enhanced to enrich their colour, giving them a distinct tone, like yellow or pink, whatever may be desired.

The HPHT method exposes stones to extremely high temperatures and very high pressures. In fact, the conditions are similar to those in which the stones were formed millions of years ago. The treatment is irreversible, as it essentially upgrades the diamond's color. Depending on the original stone, the change in color can be slight, or quite dramatic.

Certain diamonds can be processed to create white or near white diamonds using the HPHT treatment.

On client's approval, the diamond is submitted to our lab for HPHT processing. This process usually takes 10 to 15 business days. The stone is returned to the client as soon as it is ready.

The CVD method was created in the 1980s, making it newer than the HPHT method. The CVD method imitates how diamonds form in interstellar gas clouds. The CVD method uses less pressure than the HPHT method as well as smaller machines.

The CVD method places a diamond seed in a vacuum chamber. This chamber becomes filled with carbon-rich gases and is heated to nearly 1500 degrees Fahrenheit. The gas turns into plasma from these extremely high temperatures, causing the release of carbon pieces. These carbon pieces become layered onto the diamond seed, which grows the diamond.

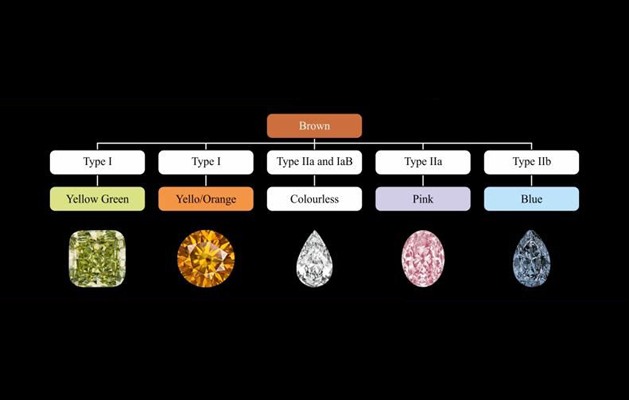

The CVD process produces Type IIA diamonds, which are extremely rare for naturally occurring diamonds. This can help scientists determine if a diamond is lab-grown or earth-grown. Type IIA diamonds are the most chemically pure diamonds. CVD diamonds are not magnetic like HPHT diamonds can be.

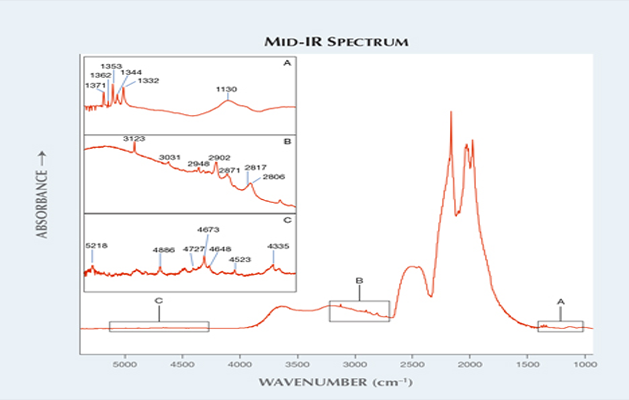

Low-pressure, high-temperature (LPHT) annealing of yellow-to-brown type Ia natural diamonds was performed to monitor its effects on optical centers within diamond, changes in the observed color, and to assess the process's viability as a commercial gem treatment.

With LPHT annealing only, the mostly brown diamonds showed a shift towards yellow coloration; Vis-NIR absorption spectra showed this change was due to a modest increase in H3 intensity. Even at long annealing times (24 hours at 1800°C) or annealing at high temperatures (2000°C for five minutes), the diamonds did not significantly lose brown coloration.

LPHT annealing showed itself as an ineffective means to break apart the vacancy clusters causing the brown color or causing nitrogen disaggregation, which resulted in only a small H3 generation. With LPHT annealing, "amber centers" — a group of several independent bands in the IR between 4200 and 4000 cm-1 that disappear with HPHT annealing — were seen to anneal out gradually at various temperatures from 1700–2000°C.

In contrast, high-pressure, high-temperature (HPHT) annealing effectively removes brown color at similar time/temperature conditions. Without the high stabilizing pressure provided by HPHT annealing techniques, the LPHT annealing showed pronounced damage on inclusions and dramatic surface etching.

In subsequent experiments, LPHT annealing was used as a follow-up to laboratory irradiation. The irradiation-related vacancies created greater concentrations of H3 and the vacancy-assisted disaggregation of nitrogen created donors which led to a high concentration of H2 centers. This combination of defects resulted in a pronounced and favorable shift towards saleable yellow colors.

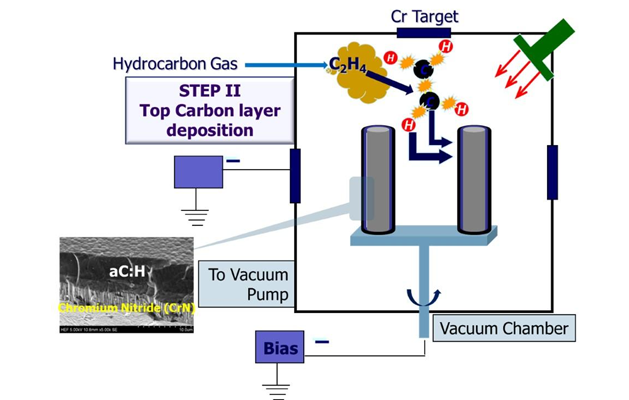

Diamond like carbon can be removed by a unique process developed by us which removes the excess DLC layer surrounding the rough CVD diamond.

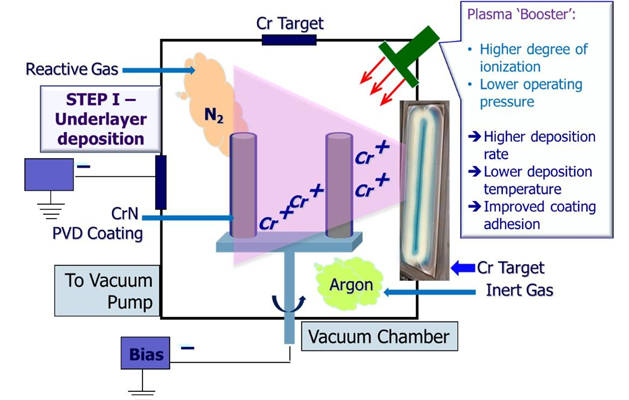

After going through a multistep pre-cleaning process, the parts are placed on a planetary fixture capable of single, double or triple-axis rotation. The planetary fixture is then placed into the vacuum chamber and the chamber is evacuated and put under vacuum.

After the chamber reaches the preset vacuum level, low-temperature preheating begins. Next the product is bombarded with ions of argon gas to scrub or sputter-clean the surface and remove micro-oxides and micro-contamination.

The first step in the coating process is to deposit an underlayer using a high-energy PVD sputtering process developed to deposit a dense, well adhered, smooth under layer.

The DLC coatings will usually include several layers of different materials as an underlayer, such as Cr, CrN, W, WC-C or Si, with a top layer of amorphous carbon, with hydrogen.

Treated diamonds are natural diamonds that have been subjected to one or more treatments or enhancements to change the physical appearance of the diamond. Some of these treatments are permanent and some are temporary.

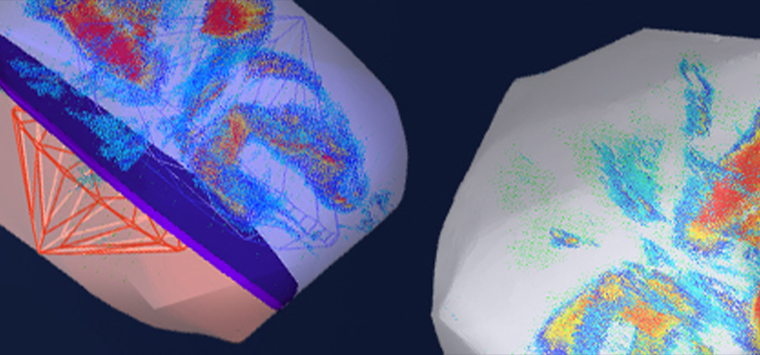

The internal structure of a diamond includes areas of physical stress, or tension. These areas develop naturally as the diamond forms. Tension within a diamond can be mild, moderate or extreme. The tension areas cannot be seen by the naked eye, yet they are a real source of stress to diamond cutters and manufacturers.

This process helps in reducing the stress (Tension) from the CVD diamond block. The damage caused to the CVD diamonds during shaping, laser sawing, and polishing can be reduced by the Tension removal process.

Special process or very small diamonds at very low cost.

CVD diamonds that size from 3+ to 13- (Diamond Sorting Sieve) round and fancy shapes (Below 0.10ct) are processed with low pressure and low temperature to remove the brown colour and improve the grade of the diamond easily by 2-3 Grades.

State's Client

Employee

Years Experience

Happy Customers